litho printing Explained: A Primer for Newbies

litho printing Explained: A Primer for Newbies

Blog Article

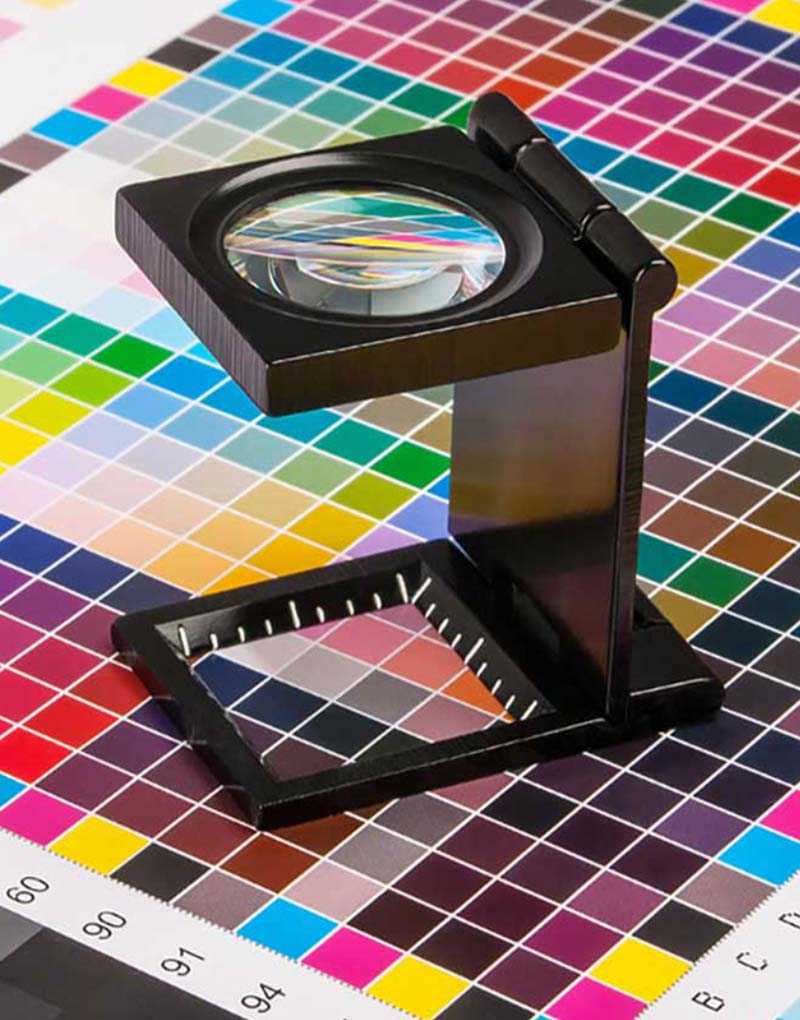

A Comprehensive Guide to Comprehending Litho Printing Strategies

The world of litho printing, a technique originating from the late 18th century, is an interesting mix of background, science, art and innovation. This thorough guide will unwind the complexities of this printing technique, from the make-up of litho inks to the challenges faced in modern-day applications. As we venture into the complexities of lithography, the relevance of automation and sustainability in ensuring its future importance becomes increasingly clear. Keep with us as we journey right into the fascinating world of litho printing.

The Historic Advancement of Litho Printing

The historical trajectory of litho printing, a crucial technology in the world of communication, is an exciting tale of human ingenuity. The process evolved with the arrival of the rotating press, which significantly increased productivity. Each phase of litho printing's development showcases humankind's ruthless quest of efficiency and top quality in visual interaction.

Translating the Scientific Research Behind Litho Printing Inks

Moving on in the expedition of litho printing techniques, the focus now shifts to the scientific research behind litho printing inks. The make-up of these inks, their drying out procedure, and color mixing techniques create the backbone of this complex art type. Comprehending these components is vital to mastering the craft and attaining the desired print results.

Composition of Litho Inks

In lithographic printing, the fundamental duty of litho inks can not be overstated. Pigments, the color-providing components, are finely ground fragments put on hold in the vehicle, a liquid that carries the pigment onto the printing surface area. Each element plays a crucial part in the final print's quality, making the exact formula of litho inks an intricate scientific research.

Ink Drying Process

From the composition of litho inks, focus transforms to the remarkable process of ink drying. 2 main techniques are utilized in litho printing: oxidative drying out and absorption. Absorption, on the other hand, involves the ink seeping into the paper fibers, which is a quicker procedure yet can lead to less dynamic colors.

Shade Mixing Methods

While the drying procedure plays an essential role in litho printing, the science of shade mixing techniques holds equal importance. The scientific research behind litho printing inks additionally takes right into account the transparency of the ink, which impacts just how colors overlay and mix.

The Art and Layout Components in Litho Printing

Litho printing takes a breath life into art and design via its unique elements. The procedure includes producing an image on a lithographic limestone plate or metal plate with a smooth surface area. The photo is after that published onto a medium, typically paper, by transferring the ink from the plate. What collections litho printing apart is its ability to reproduce elaborate designs with high fidelity, making the output almost identical to the original artwork. This is accomplished with using various line strategies such as stippling, hatching, and cross-hatching, which enable a variety of tonal effects. Litho printing accommodates a variety of colors, allowing artists to create vibrant and lively prints. This combination of precision and adaptability makes litho printing a preferred option for several musicians and designers.

Modern Applications of Litho Printing Techniques

Litho printing techniques have discovered comprehensive usage in the contemporary industrial sector. Its influence and significance proceed to grow with the introduction of brand-new technologies view publisher site and technologies in the field. This section will discover these contemporary applications and the transformative duty they play in the printing industry.

Business Litho Printing Uses

Litho printing remains a crucial component of the commercial field. High-volume printing tasks, such as the manufacturing of books, newspapers, and product packaging, count on litho printing for its capability to supply remarkable image top quality and expense performance. Litho printing additionally gives a wide shade range, remarkable to that of electronic printing.

Advancements in Litho Printing

Pressing the limits of standard methods, modern improvements have actually fueled a host of advancements in litho printing. One popular growth is electronic litho printing, which combines the virtues of electronic technology with litho's top quality outcome. These innovations highlight the long-lasting relevance of litho printing in the modern globe.

Checking out the Process of Litho Printing: Detailed

Difficulties and Solutions in Contemporary Litho Printing

In spite of the precision and practice that litho printing proudly promotes, it is not without its set of modern challenges. Digital litho printing permits for affordable short runs and easy modification, dealing with the issue of variable information. Thus, while there are difficulties, the litho printing industry is proactively adapting to satisfy them head-on, guaranteeing its relevance in the future.

Conclusion

Finally, litho printing, with its rich history and scientific complexities, holds a significant location in the print sector. read review As the guide discloses, it's a synthesis of art and innovation, with modern-day innovations guaranteeing its significance. The industry deals with difficulties that require innovative remedies, with an emphasis on automation and sustainability. The future of litho printing pivots on its capability to adapt to these transforming demands, verifying its enduring value in an evolving market.

Report this page